How Leather is Tanned

Tanning leather is a very important process to preserve the life of the animal hide. Without tanning, the hide will rot and become unusable in any manner. Due to the importance of tanning we are going to go over how leather is tanned and different ways leather is tanned.

History of tanning leather

Tanning leather has been found to date back thousands of years due to archeologist sights. Finding leather material that has gone through a similar process has survived many centuries.

Humans that lived in the B.C. era dating as far back as 3300B.C. used a substance called ‘tannin’ to process leather.

Tannin was a natural chemical found in many plants and trees. But most of the chemical was gathered from grapes, oak and even tea leaves.

This substance forms a bond with the leather making it much more durable and less likely to rot. Just as today, the process was extremely smelly but well worth it as it allowed for this skin to be used.

This is where the term of tanning originated from due to the tannin chemical used throughout previous centuries.

Even in wine, while going through the fermenting process absorbs tannin from the squashed grapes. This is what brings out the distinct flavor in the wine.

Just as leather crafting evolved throughout the years so did processing leather. Many centuries later we now have a a few different methods of tanning leather to choose from.

How leather is tanned

Due to the different methods used for tanning leather, this can cause a different feel and outcome of the leather.

Once the hide is skinned from the animal it almost immediately will need to be soaked into water and salt. As the skin will have no natural oils being produced it will need to be dunked into a substance to avoid rotting.

If the hide begins to rot it can still be cut to save the fresh parts of the hide. But if leather starts rotting it can easily grow throughout the whole hide.

Next the hide will be cleaned, cured and the removal of hair will take place. Any flesh will need to be trimmed off the underside of the hide. Then the leather will go through a process to remove the hair.

A common way this will be done is called a liming process that uses a very potent chemical, usually an alkali mixture.

The hide will either be placed into a rotary drum or in a large container stirred with a paddle in the mixture.

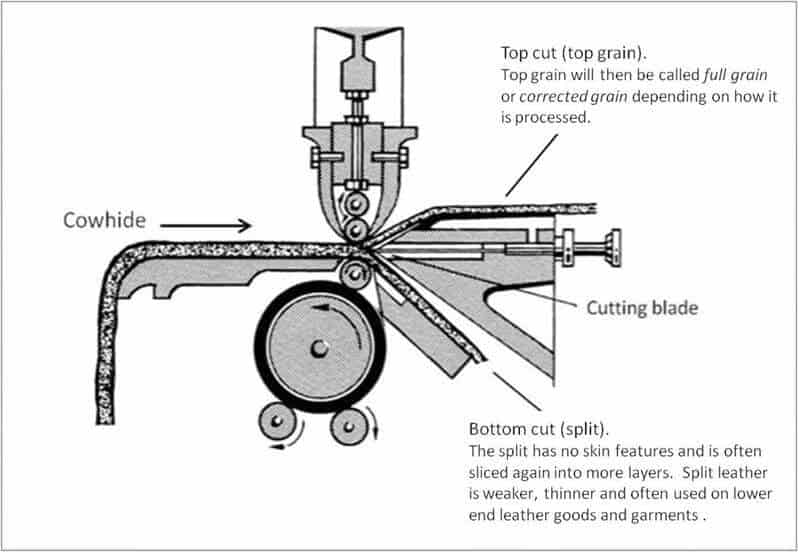

This will remove all the hair, any unwanted protein, and will swell the leather up. Swelling the leather will make the splitting (cutting process) much easier. After limming is complete the hides will be soaked in a bath to clean off the liming chemical.

Once enough time has passed the hide will be taken out then immediately a tanning agent will be applied. This agent will be placed onto the leather before it has dried and been rinsed.

Lastly after the tanning has been completed the leather will go through its cutting process to produces various sizes and weights. This process is known as “splitting” which cuts through the middle of the leather. Producing the bottom (split) side and the top side of leather. These cuts can produce different types of leather such as sued or full grain.

Although this is a general process, it is pretty common throughout the different types of tanning. So let’s go over the different ways on how leather is tanned.

Veg-Tanning

Veg-tanned leather is very desirable by leathercrafters and used in high end items.

Due to the substances used in vegetable tanning this will make the leather very sturdy, able to be wet molded, stamped and carved. Although this leather is sturdy it is also very flexible. This is why wet molding can only be done with veg-tanned because it can be soaked to allow more flex. Once sat in a flexed position it will dry back to more sturdy state while shaped.

Veg-Tanned leather can easily take different shapes and methods to adding shapes.

Although the name, vegetables are not used in tanning the leather, instead many organic items are though.

The most common substance used is Oak bark. This is where the natural beige, brown and even red/yellow tints are produced. And due to the material used it creates a very original tanning of the leather. Making every hide result in different tones and even different shades on the same piece.

This method is much more environmentally friendly due to the organic material used in the process. And since the leather is not soaked with chemicals it allows for more breathability. Allowing for the leather to grow a nice patina (worn look) after aging and usage.

The downside of Veg-tanned

Tanning through this method takes a very long and hands on approach to complete. This process has become an art in itself of mastering and can vary in price due to who is tanning the leather. This process can take anywhere between two months to a year for one single batch. This is why you pay for a higher price when buying.

Chrome Tanning

Chromium tanning is the most common method in tanning leather and makes up to 80% of the leather made today.

Chromium sulfate and a small amount of other chemicals are used during this process. Due to the chemical compounds it will allow the leather to easily be tanned into many colors.

This leather is very soft and flexible plus the material becomes very resistant due to the chemicals. The process also takes a very short time as one batch can take on average just two days to finish. Allowing the leather to be sold at a much cheaper price.

Disadvantage of Chrome Tanning

Due to the chemicals used in this process, it is more harmful to the environment as the chemicals cause strong fumes. It should also avoid holding metal items as the salt in the chemicals can cause friction between metals wrapped around the leather. Some examples would be holster for guns and sheaths for knives.

Very low breathability leading to almost no patina which could be an advantage depending on what your preference is. This leather can also not be stamped, molded or carved as it is very loose and flexible. It will struggle to take shape which makes it very unpopular for leather crafting.

Other Noteable Methods of Tanning

There are still a few different methods used in tanning hide that are not as common but still worth noting.

Brain Tanning is actually a method, and it pretty much is what it sounds like.

This process is about 100% environmentally friendly (as you can guess) but is near impossible to be done on a big scale. This is more common for hunters or a single person that has the whole animal. The person will take on a very hands on approach to tanning hide.

When brain tanning you will still need to take it through soaking, and cleaning processes. Except instead of oak or chromium you will use parts of the brain that can be soaked up by the leather. When brain tanned, the leather is much more water resistant than chrome or veg-tanning.

This was very common among Native Americans when they made leather gear.

Aldehyde Tanning– Glutaraldehyde or Oxazolidine compounds can create what is called “wet white” leather. This is due to the leather becoming very pale in color. Aldehyde tanning is not as popular but does advertise as “chrome free” tanning. So it does seem to be a bit more natural than using strong chemicals for tanning.

Chamois Tanning – Is a form of Aldehyde except marine oils (mainly cod oil) will be used in the process. This type of leather can be found in vehicles and small shoes. Tanning this way is much more natural as it uses oils produce by fish and other sources containing high source of omega-3.

Alum Leather- Is a tanning process using aluminum salt mixed with chemicals and protein such as flour or eggs. It is not too desired as it can be easily “untanned” if soaked in water.

Where your leather is tanned

Just about 90% of hides that are produced and sold in the United States are actually outsourced to other countries to be tanned.

Due to companies in the past disposing of their liming chemical improperly, the United States and Europe struck down on tanning companies. They placed laws around the disposal of these chemicals. Although the leather is not tanned in the states, the leather produced is in very high demand around the world. This is because compared to other places, the U.S. tends to take much better care of their cattle.

If you buy leather in the U.S. your leather is most likely going to be tanned in Leon, Mexico. They are known as the “shoe capital of the world” due to their high leather products.

You can also spend the extra buck to pay for Italian leather, but it isn’t actually made in Italy. This is what I meant by the tanning process as an art, as Italy has some of best methods when tanning. When you see “Made in Italy” it is not that the cattle had come from Italy but has been tanned there.

China has another big processing section of leather but is usually frowned upon due to their regulations being less strict. This can be anything from the working environment to the general world environment. But this is not the case for every place in China. So leather coming from China could not be as bad as it sounds. The negative view also is relevant since we see “Made in China” everywhere and assume it’s cheap goods.

I hope that went over the process of how leather is tanned and some different methods of tanning. Every type of leather has its own pros and cons and it’s up to the crafter to decide what suits them.